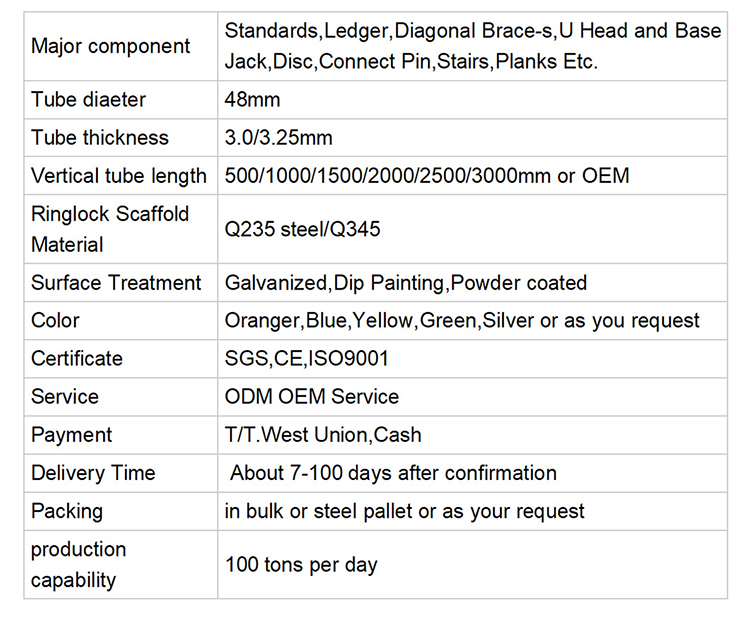

Premium Scaffolding Solutions – Safe, Strong, and Smart

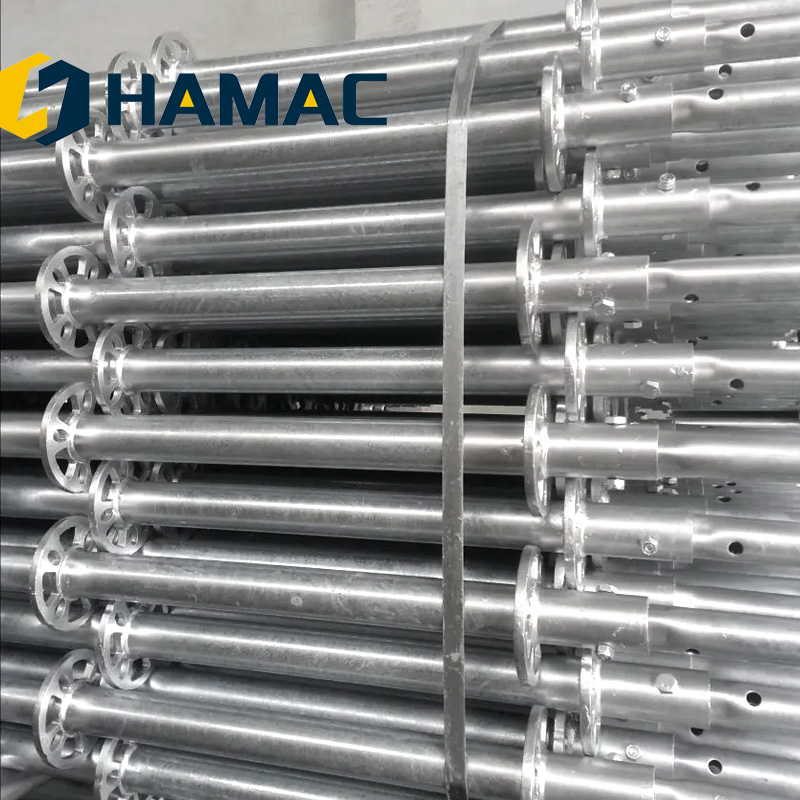

At HAMAC, we provide high-performance scaffolding systems engineered for safety, efficiency, and adaptability. Whether you’re working on high-rise construction, industrial maintenance, or residential projects, our scaffolding delivers unmatched stability, quick assembly, and compliance with global safety standards.

Why Choose Our Scaffolding?

✅ Built for Safety – Robust materials and fail-safe designs to protect workers at any height.

✅ Fast Setup & Dismantling – Modular components for reduced labor time and costs.

✅ Versatile Configurations – Adjustable for complex structures, from facades to bridges.

✅ Durable & Lightweight – High-strength steel/aluminum for longevity without excess weight.

✅ Cost-Effective Options – Purchase or rent scaffolding tailored to your project’s scale.

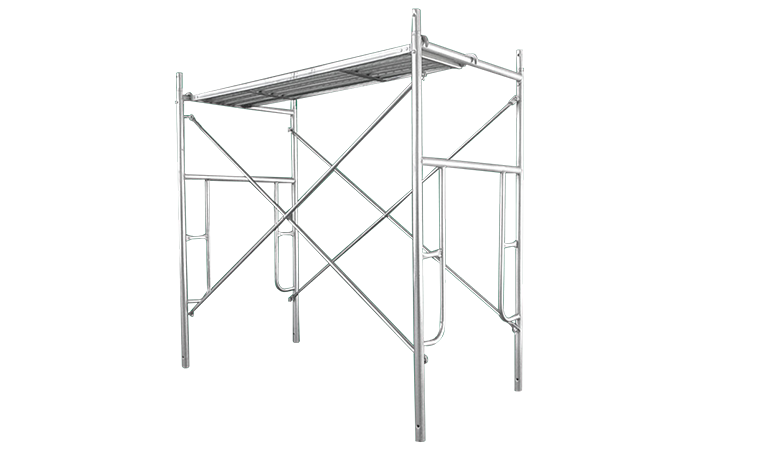

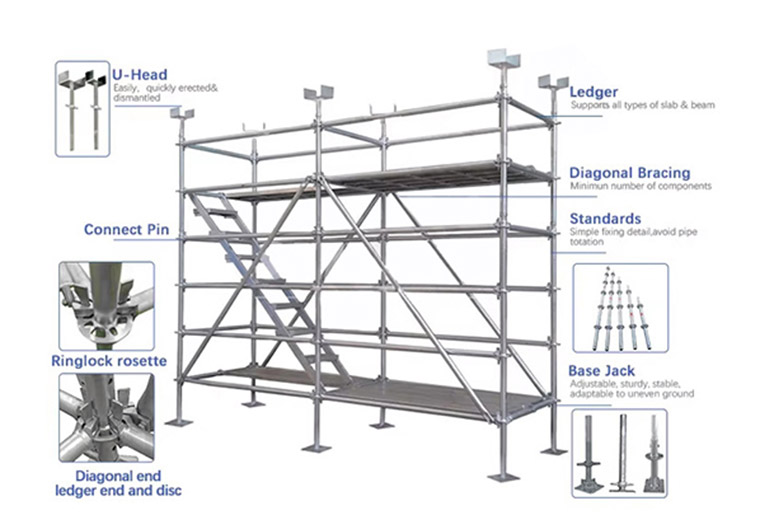

Ring lock scaffoldings offers the best frame-body stability in its class with the support of complete vertical rod, bar, horizontal-diagonal and vertical-diagonal structure in the 3D space providing a complete lattice system.

They are quick and easy to assemble from its fewer set components offering ease of storage as well as transportation.

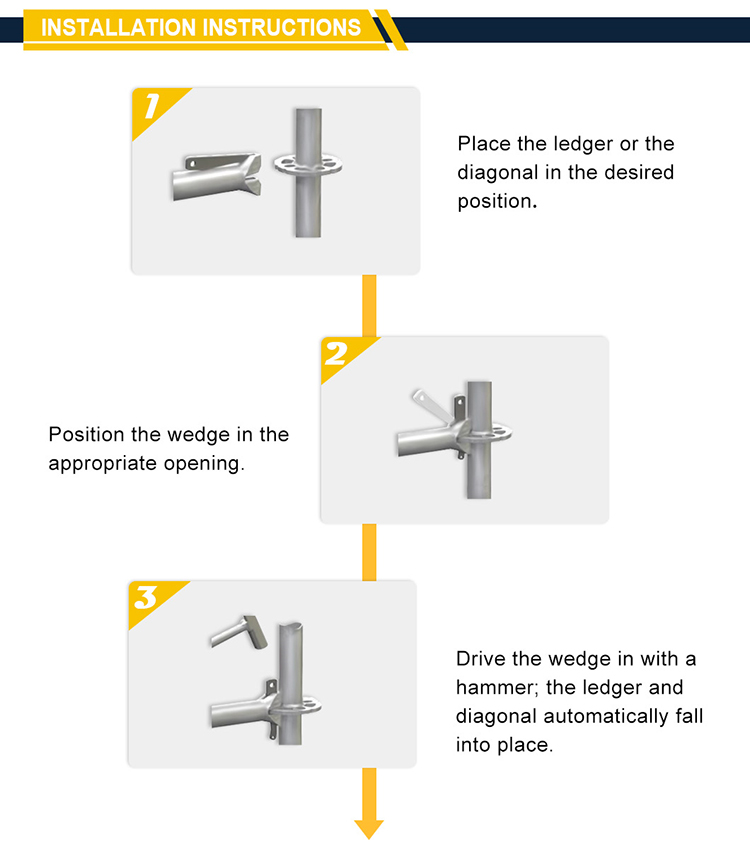

Scaffolding Installation Guide – Safe & Efficient Setup

Proper scaffolding installation is critical for workplace safety, structural integrity, and project efficiency. Follow these steps to ensure a secure and compliant setup.

1. Pre-Installation Preparation

✔ Inspect Components – Check for damaged tubes, boards, or fittings before assembly.

✔ Clear the Site – Ensure a level, stable base free of debris and overhead hazards.

✔ Review Regulations – Comply with local safety standards (OSHA, EN 12811, etc.).

2. Base Assembly & Stability

✔ Use Base Plates & Soles – Prevent sinking by placing load-bearing plates on compact ground or mudsills.

✔ Level the Foundation – Adjust screw jacks or use shims to eliminate unevenness.

✔ Install Guardrails First – For tower scaffolds, secure guardrails early to prevent falls.

3. Structural Assembly

✔ Erect Standards Vertically – Use spirit levels to ensure upright alignment.

✔ Connect Ledgers & Transoms – Follow manufacturer spacing guidelines (typically 2–2.5m apart).

✔ Secure Diagonal Braces – Reinforce stability by adding cross braces at every level.

4. Platform Installation

✔ Lay Scaffold Boards – Ensure full coverage with no gaps (>50mm overlap on supports).

✔ Lock Boards in Place – Use hook-shaped retainers or metal clips to prevent movement.

✔ Add Toe Boards – Install at edges to stop tools/materials from falling.

5. Safety Checks & Dismantling

✔ Daily Inspections – Look for loose fittings, corrosion, or shifting before use.

✔ Avoid Overloading – Adhere to maximum load limits (e.g., 2x kN/m² for light-duty scaffolds).

✔ Reverse Order for Dismantling – Remove platforms, then braces, and finally standards.