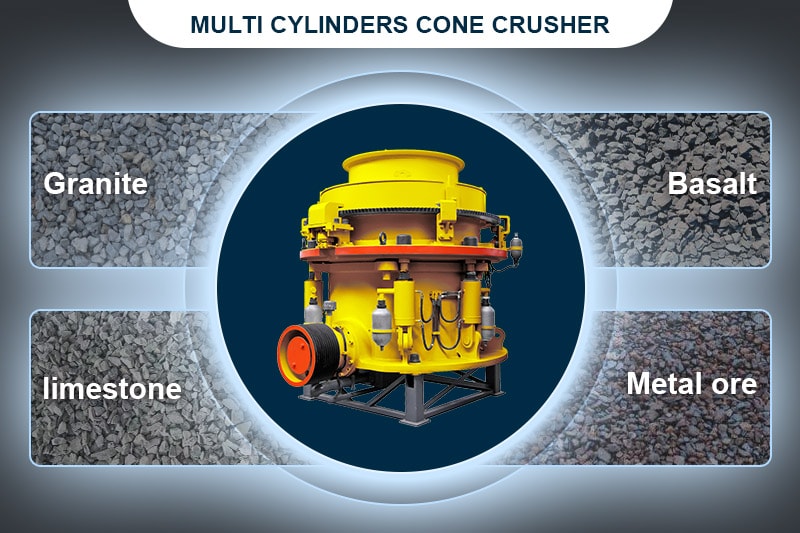

Brief introduction of hydraulic cone crusher

For the hydraulic cone crusher, it is different from the spring cone crusher for sale. Its protection device is the hydraulic system. That is why it is called as hydraulic cone crusher.

The crusher is the improved type of spring cone crusher and can be used to replace ordinary hydraulic cone crusher in the field of mining and construction.

The technology of HPT series multi-cylinder hydraulic cone crusher can obtain larger output capacity in smaller space with less or smaller volume of equipment. The HPT multi-cylinder hydraulic cone crusher adopts the full chamber feeding to realize the unique "inter-particle lamination crushing". When the material passes through the crushing chamber, the principle of multiple crushing action makes the particle size more uniform. For aggregates production, the cubic shape of the product meets the sand and gravel industry standards, thereby bringing greater investment benefits to users.

Working Principle of hydraulic cone crusher

As it is shown, the motor drives eccentric bushing revolve via V-belt, driving shaft and bevel gear. The mantle is revolved under the action of eccentric bushing. Sometimes the concave is near to mantle, and sometimes the concave is far from mantle. The raw material is being pressed and impacted all the time in the crushing chamber. Then the crushed the material is discharged from the discharge opening.

Advantages of hydraulic cone crusher

1. High efficiency: The cone crusher machine adopts the optimized structure of fixed main shaft and small spherical shaft, which is 5% ~ 15% higher than the efficiency of the old spring cone crusher for sale;

2. Large production capacity: The hp cone crusher is designed with a perfect combination of crushing stroke, crushing speed and crushing chamber shape, so that the output of this machine is 35% ~ 60% higher than that of the old spring cone crusher under the same crushing cone size.

3. High-quality aggregate: The crusher cone adopts the unique lamination crushing principle to produce the crushing effect between different aggregates, so that the proportion of cubes in the finished product is significantly increased, the needle-shaped stones are reduced, and the particle size is more uniform.

4. More stable operation: When there are hard objects such as iron blocks that can not be broken into the cone crusher liner, the over-iron protection device will automatically release it and then reset it immediately.

5. Multi-point split hydraulic lubrication control system can ensure double protection of bearing lubrication and overload protection of the machine.

7 factors need to be noted when hydraulic cone crusher is working.

In order to make sure the rock crusher cone works at higher efficiency, and protect the cone crusher machine so that its service life is longer. Here are 7 factors need to be noted.

1. The feeding size is not allowed to exceed the maximum feeding size allowable;if the feeding size is too big, the material will skid in the crushing chamber but can not be crushed, the capacity will be lower. Meanwhile, if the feeding particle size is too large, it will have a greater impact on the cone crusher, affecting the normal use of the cone rock crusher, and even causing the cone crusher machine downtime;

2. The discharge opening is not allowed to be smaller than the minimum discharge pening size of the corresponding cone crusher cavity type.If the discharge opening is too small, it will cause high load current and cause damage to the hydraulic cone crusher, such as burning of copper sleeves, premature damage of cone crusher parts.

3. Uniform feeding in full crushing cavity is required.Uneven feeding or inability to feed in full cavity will cause large fluctuations in the load current of the cone crusher, decrease in output capacity, uneven wear of the cone crusher wear parts, and shorten the life of the cone crusher bowl and mantle;

4. The operating load is generally 75%~90%.According to the material crushing situation, the cone crusher load is controlled at 75%~90%, preferably not more than 90%. If the load is too low, the lamination crushing can not be achieved, and the cone crusher can not exert its superior performance; if the load is too high, a large load will be generated on the copper sleeve of the cone crusher, which will shorten the life of parts such as the copper sleeve.

5. Strictly control the moisture content when the feed contains viscous materials,it is easy to cause the crushed materials to be difficult to discharge into the crushing cavity, and the load current of the cone rock crusher increases, resulting in shutdown. Therefore, when crushing viscous materials, the moisture content must be controlled, generally not exceeding 5%.

6. Avoid the jumping of the support sleeve;the jumping of the support sleeve will damage the copper seat lining and also damage the main frame. The main reasons for the jumping of the support sleeve are: ①The pressure of the safety cylinder is too low; ②The feeding is uneven, with more material on one side and less material on the other side, and the load is uneven; ③The feeding is too large, the load is increased, and the normal crushing of the material is affected. ;④The discharge opening is too small and the load increases.

7. Control the lubricating oil temperature;The viscosity of the lubricating oil is a main indicator to ensure the lubricating effect of the multi-cylinder hydraulic cone crusher due to its large eccentricity, high power and large calorific value. The cooler in the lubrication system can reduce the lubricating oil to a suitable temperature, so that the lubricating oil has a good lubricating and cooling effect.