What is dry batch concret

Dry batch concrete plant is a concrete batching plant without central concrete mixer, this is the most important difference compared with wet batch concrete plant. It is dry mix. All the aggregates, sand, cement and water will be discharged into the concrete transit mixer without mixing. It includes the aggregate weighing system, feeding system, water supply system, bolted type cement silo and weighing system. Its structure is more simple compared with stationary concrete batching plant with a central mixer. Because without the mixing procedure, it will save time for mixing, the concrete can be mixed in the concrete transit mixer truck, so it saves time as well. This kind of dry type concrete batching plant is widely used in many countries such as Philippines, Peru, Chile, Ecuador, Dominican etc.

Features of concrete dry batch plant

1. Simple but reliable structure design, make the cost lower, to save the investment for the clients;

2. Without central concrete mixer, low maintenance cost; and save the cost to buy a concrete mixer;

3. The total power of a dry type concrete batching plant is lower, it can save the cost for electricity;

4. Concrete is mixed in the concrete transit mixer, save the time for mixing in the concrete batching plant; While the mixer truck is going to the construction site, it keeps the rotation order to prevent tampering, hardening of the mixed concrete and to ensure the freshness of the materials.

5. It can be moved from sites to sites, easily and conveniently;

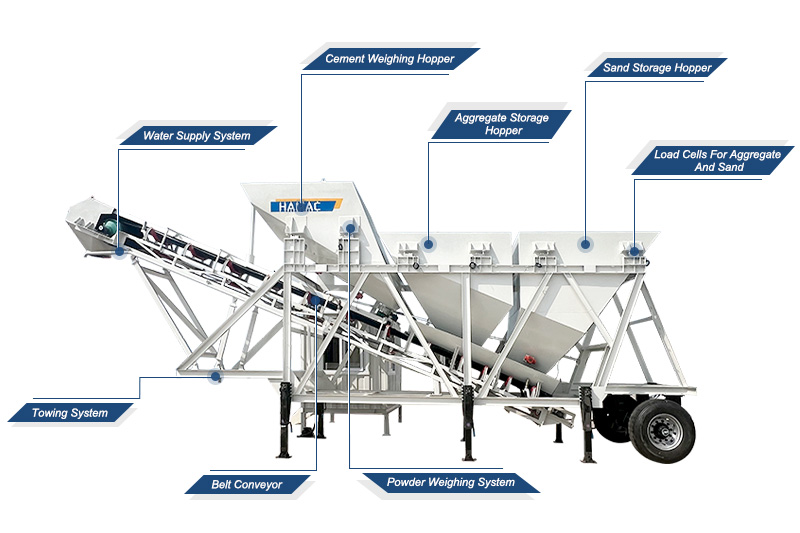

Components of dry type concrete batch plant

1. Aggregate pre-feeding systems are our alternative solutions to the loading ramps which are necessary for charging the hoppers by wheel loaders. In case of using aggregate pre-feeding systems, requirement of loading ramp is removed.

2. Belt conveyor, it is used to transport the aggregate and sand into the truck concrete mixer;

3. Weighing system, there are load cells for aggregate, sand and cement, these different materials will be weighed firstly, and then fed into the mixer truck;

4. Control system, dry type batching plant is equipped with high-tech automation system including top class SIEMENS – SCHNEIDER brand electronic components and PLC . The whole system is controlled through an advanced software which is sophisticated features and user friendly interface.

5. Cement silo or cement hopper is used to stock the cement. HAMAC dry type concrete plant can be equipped with different size of cement silos from 50 to 500 tons storage capacity according to the needs and conditions of our clients’ projects. If the cement is supplied in bags, the cement is filled to the silos easily by means of a big bag opening and silo charging systems which can be integrated to the dry mixing plant.

6. Water supplying system, the water is supplied into the concrete mixer truck by a water pump which is controlled by time relay. It control the water quantity via controlling the working time of water pump.

What is the price of dry batch concrete plant?

The price of the concrete dry batch plant for sale is related to the model and configuration specifications, such as: the capacity (how many cubic meters per hour) and configuration. At present, we can provide you with the dry batch concrete mixing plant with different capacity from 25m3/h to 75m3/h. For the components of this plant, the brand of pneumatic cylinders, vibrators, motor brands, air compressors etc, all of these will affect the price. The best way is you can provide our expert with your detailed requirement, then we can give you an exact price.