Brief introduction of hollow block maker machine

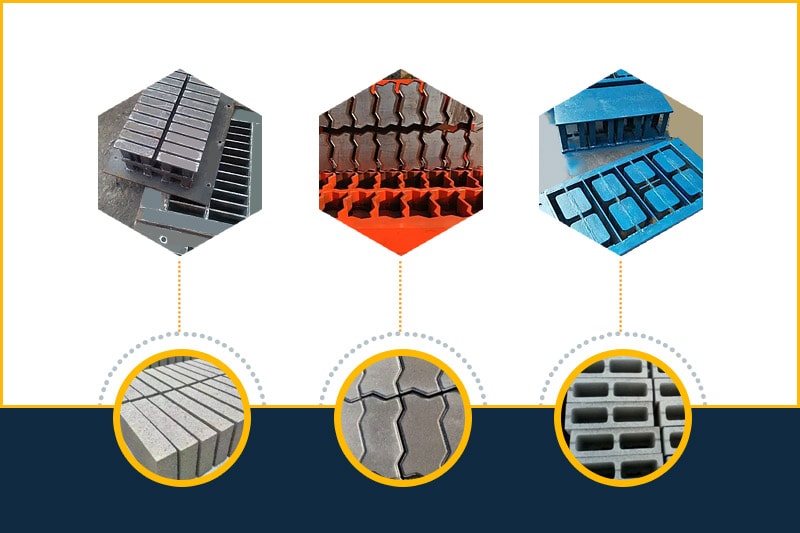

Hollow block machine is the device for producing various hollow blocks and paver bricks. You can just change different molds for different sizes blocks or bricks on the HBM.

Then you can produce different blocks and bricks such as: Eco brick, insulating block, hollow block, holes block, solid block;

And paver blocks, such as: interlock block, Dutch block, curb; as well as concrete members, dry base brick, planter bricks, fence block for parks, air port and wharf etc.

Types and models of hollow block machine

HAMAC can provide you with egg-laying mobile concrete block machine, manual block machine, semi-automatic concrete block machine and full automatic hydraulic concrete brick making machine for sale as options to produce different hollow block size.

There are many different types and models concrete block making machine in the market. According to different standard, we can divide them into different type.

Mobile type, also name egg-laying concrete block making machine, it can be moved all the time, and the block is produced on the ground, no need the pallet. It is suitable for some small factories with big working areas;

Stationary type, it is suitable for medium and big scale concrete block factory. Its capacity is much higher, so you need the pallet to take the concrete block to the curing area to stock them;

We can design the hollow block factory for you according to the land you have. We have the working sites in different areas of Philippines. You can visit them for a clear idea.

Features of cement hollow block making machine

- 1. Strength of brick, bricks of different grades of strength can be produced according to the requirements of engineering construction

- 2. Shape, according to the needs of the project to determine the different design specifications of hollow blocks dimension, cement bricks, paver bricks etc

- 3. It can be used to produce hollow blocks, multi-row perforated bricks, solid bricks, paver bricks, decorative bricks, wall bricks and other concrete bricks of different varieties

- 4. Waste concrete bricks can also be recycled, increasing the comprehensive utilization of resources

Different hollow block machine design

According to different factors, we can divided the cement brick machines to many different types

- 1. Degree of automation, there are automatic cement brick machine, semi-automatic cement brick machine and manual cement brick making machine;

- 2. Forming principle, there are mechanical vibration cement hollow block machine and hydraulic forming cement hollow block machine for sale;

- 3. Mobile or stationary, there are mobile concrete hollow block machine and stationary concrete hollow block machine. The mobile type is also named as portable cement hollow block machine or egg laying cement brick machine;

The client can choose the suitable hollow block machine design for their different projects.

How much is hollow blocks?

People always want to know the price list of hollow blocks, but the price is different if the dimension of cement bricks is different. According to our experience, we can provide you with some standard and popular size of hollow block design for sale in the market. They are different hollow block dimension.

So, you have to confirm the hollow blocks size firstly, and then consult the price from the concrete hollow block suppliers in your country. Sometimes, its price will be affected by the aggregate and sand price, cement price etc.

How to choose a right model of hollow block making machine?

It is good business for concrete blocks. The hollow blocks price in the world is higher and higher in these years. If you want to invest on the concrete hollow block business, there are several factors needs to be considered before purchasing

- 1. Your budget, it is the most important factor needs to be considered;

- 2. What is the most popular block size, brick size or paver size in your country?

- 3. What is the hollow block price, bricks price, chb price or paver blocks price in your country?

- 4. How many pieces block or brick you want to produce per day or per hour?

- 5. How many workers you want to employ? Then you can decide to use automatic hollow block machine or semi-automatic hollow block maker.

- 6. Do you have enough land to arrange the concrete block machine there?

You can also contact our HAMAC expert for professional consultation. We will consider your budget and actual market condition together and then recommend you a suitable concrete hollow block production line.

Look for a reliable cement brick maker manufacturer

There are many cement hollow block machine suppliers in the world, how can you find a reliable one?

- 1. Visit the factory or working sites of the suppliers of hollow block machine in your country, to check the quality firstly, to see the paint, welding etc;

- 2. Compare the concrete hollow block production line cost, to consider the price and quality together;

- 3. Check the after-sale service of concrete hollow block maker, to see if you can get the service shortly; HAMAC owns local office in Manila, we can provide the clients with service immediately;

- 4. Call the clients who are using the CHB machine in your country to check with them how the quality is.

After considering all these factors, you will finally find a reliable concrete hollow block making machine in the market.