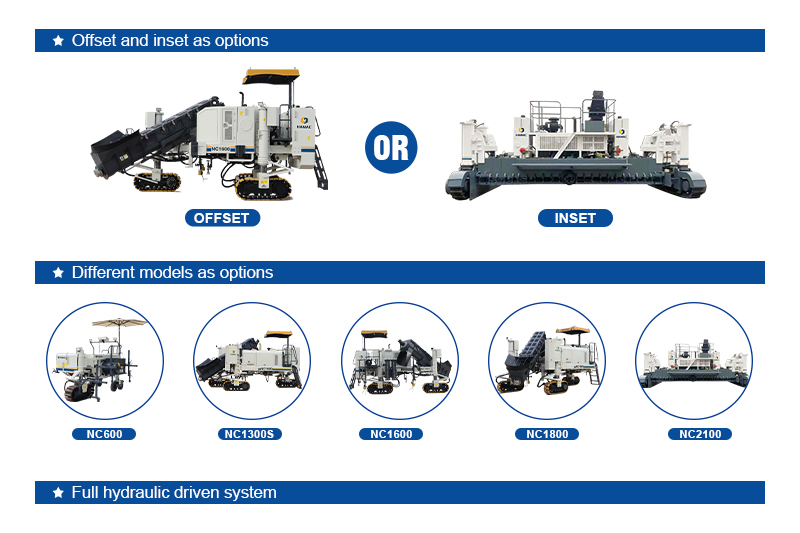

Offset pavers are used to produce monolithic concrete profiles such as protective concrete walls, kerb profiles, gutters or narrow paths. Thanks to numerous options, such as for concrete feeding or slipforming, offset slipform pavers are extremely versatile. Inset pavers cost-effectively produce concrete pavements, such as for motorways, arterial roads, runways or railway lines.

What is slipform paver machine?

Multi-functional slipform pavers is a multi-purpose cement concrete construction equipment independently developed by our company. It is multi-purpose and can realize various moldconfiguration methods. It is widely used in road drainage ditches, drainage channels, curbs, shoulder stones, concrete guardrail cement concrete structures, farmland water conservancychannels and other construction fields. It replaces the traditional process and significantlyimproves the construction quality and speed of cement concrete structures. With slipform pavers, the concrete is placed directly in front of the machine and distributed by aspreading auger or spreading plough. Vibrators compact the concrete homogeneously and themold forms it in the specified width and thickness as the slipform paver advances.

With slipform pavers, the concrete is placed directly in front of the machine and distributed by a spreading auger or spreading plough. Vibrators compact the concrete homogeneously and the mold forms it in the specified width and thickness as the slipform paver advances.

It features a large power reserve, full electronic control, full hydraulic power drive, proportional control, three-track traveling, automatic steering and leveling control system, and can complete the technological processes of vibrating, paving, and extrusion forming of cement concrete structures at one time.

What are the advantages of slip form pavers?

What is the slipform paving technique?

Slipform paving is defined as a process used to consolidate, form into geometric shape andsurface finish a PCC mass by pulling the forms continuously through and surrounding theplastic concrete mass. Slipform paving is most appropriate for larger jobs that require highproduction rates.

Technical Data of slipform pavers

| Series Number | ||||||

| 1. Basic performance parameters | Maximum side paving height | 600mm | 1300mm | 1600mm | 1800mm | 2100mm |

| Maximum paving width | 600mm | 2000mm | 2500mm | 3000mm | 3200mm | |

| Paving speed | 0~15m/min | 0~15m/min | 0~15m/min | 0~10m/min | 0~15m/min | |

| Travel speed | 0~30m/min | 0~35m/min | 0~35m/min | 0~28m/min | 0~35m/min | |

| 2. Power system | Engine model | Yuchai 30D2G0-1000000WA | YC4DK120-T301 (Yuchai) | QSB3.9-C130-30 (Cummins) | QSB3.9-C130-30 (Cummins) | B3.9CS4 150C (Cummins) |

| Engine emissions | Stage III | Stage III | Stage III | Stage III | China IV | |

| Rated power/speed | 36.8 kW/2400r/min | 88 kW/2400r/min | 97kW/2300r/min | 97kW/2300r/min | 118kW/2200r/min | |

| Diesel tank capacity | 90L | 320L | 360L | 360L | 360L | |